In industrial manufacturing, PLC automation companies and PLC Programming Services in Pune are essential in transforming factory operations. As demand for precision, speed, and efficiency grows, more industries turn to Programmable Logic Controllers (PLCs) to handle complex automation tasks.

These controllers are the core of modern factory systems, controlling robotic arms, running assembly lines, and tracking electrical systems. This article will discuss how PLC companies help industries succeed, highlight current trends, and explain why professional PLC programming is vital for long-term growth.

- What Is PLC Automation?

PLC (Programmable Logic Controller) automation uses microprocessor-based units to control industrial machines and processes. These tough systems are designed to operate in tough environments. They perform logic-based tasks in real time, ensuring smooth and reliable operation.

PLC automation is widely used in:

- Automotive assembly lines

- Food and beverage packaging

- Pharmaceutical production

- Water treatment plants

- Electrical panel control systems

- Services Offered by PLC Automation Companies

Top PLC automation companies deliver complete end-to-end solutions designed for industry-specific requirements. Their services typically include:

- Custom PLC Programming

-

- Logic development using ladder logic, function blocks, and structured text

- Real-time control for motors, conveyors, and actuators

- Seamless integration with HMI and SCADA systems

- System Design and Integration

- Development of automation architecture

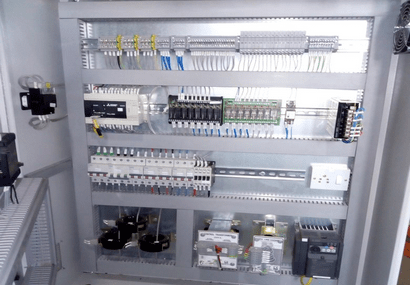

- Hardware selection and panel design

- Integration with third-party sensors, drives, and communication protocols (MODBUS, PROFIBUS, etc.)

- Installation and Commissioning

- On-site setup of PLC cabinets and field wiring

- IO testing and debugging

- Trial runs and optimization

- Upgrades and Migration

- Replacing legacy PLCs (e.g., Siemens S5 to S7, Allen Bradley to newer platforms)

- Programming backup and reconfiguration

- Support for Industry 4.0 and IoT integrations

- Remote Monitoring and Support

- Cloud-based dashboards for real-time data

- Remote troubleshooting and firmware updates

- Alarm notifications and predictive maintenance

- Current Trends in PLC Automation

PLC systems now go beyond simple logic control. They are quickly gaining new roles in smart manufacturing, data analysis, and AI-driven automation. These changes highlight the key trends for 2025.

- Integration with IoT and Cloud Platforms

-

- Real-time data sharing between PLCs and cloud systems

- Better decision-making using centralized dashboards

- Remote asset monitoring and alerts

- AI and Edge Computing in PLCs

-

- Predictive analytics to avoid machine breakdowns

- Adaptive control using machine learning algorithms

- Faster responses via edge-level computation

- Cyber Security for Industrial Control Systems

-

- Encrypted PLC communication protocols

- Firewall and intrusion detection integration

- User-based access and logging

- Virtual Commissioning and Digital Twins

-

- Simulating PLC logic before deploying on real machines

- Faster project delivery with fewer errors

- Reduced downtime during commissioning

- Open-Source and Modular PLCs

-

- Cost-effective solutions for SMEs

- Custom logic development with open platforms

- Flexibility for rapid prototyping and scaling

- Why You Need Professional PLC Programming Services

Professional PLC Programming Services ensure:

-

- Error-Free Execution – Tested logic minimizes machine downtime

- Faster Project Delivery – Experienced teams know how to avoid common pitfalls

- Future-Ready Solutions – Programming designed for scalability and flexibility

- Compliance with Industry Standards – Ensures safety and operational integrity

- Reliable Maintenance Support – Long-term troubleshooting and upgrades

- Industries That Benefit from PLC Automation

PLC automation is widely adopted across various sectors:

| Industry | Use Cases |

| Automotive | Assembly line control, robotic welding |

| FMCG | Packaging, batching, mixing systems |

| Pharmaceutical | Cleanroom automation, track-and-trace |

| Textile | Speed control for looms, dyeing machines |

| Water & Wastewater | Pump control, level monitoring |

| Energy | Load management, grid monitoring |

- How to Choose the Right PLC Automation Company

When selecting a PLC automation partner, keep the following in mind:

-

- Experience in your specific industry

- Certified expertise in major PLC brands (Siemens, Allen Bradley, Mitsubishi, Delta)

- In-house programming and control panel design capabilities

- Strong post-sales support and documentation

- Willingness to offer scalable, future-ready solutions

- Ready to Automate with PLCs?

If your business wants to make operations more efficient, PLC automation and programming are essential first steps. Working with a knowledgeable automation partner can significantly boost productivity, improve product quality, and reduce costs over time.

Upgrade Your Factory with PLC Automation

Get reliable, scalable, and cost-effective PLC programming services tailored for your industry.